Carbon Policies in Canada: Implications for Biomass District Energy Systems

Kayla Brehon

Biomass district energy (DE) systems are offering Canadians a low-carbon source of heat and/or electrical energy that can be more reliable and efficient than other renewable sources. Biomass is a term used to describe renewable materials including solid wood or wood residues such as the by-products of the forestry industry, agricultural crop residues, aquatic plants, animal wastes and dedicated tree farms (Canada Energy Regulator, 2020). DE systems are comprised of a local source of energy generation with biomass as the fuel source and equipment that connects multiple buildings in a community through underground piping. The local energy centre heats water that is pumped through pipes to local buildings for heating, cooling, and domestic hot water. DE systems can also produce electricity if cogeneration equipment is used.

This paper looked to explore the question; how do carbon pricing policies affect the implementation of biomass DE systems within Canada? The project's multidisciplinary approach incorporated energy, policy, and economics. The Sustainable Development Goals (SDGs) that would be impacted by the implementation of biomass DE systems include goal 7: affordable and clean energy, goal 9: industry, innovation and infrastructure and goal 11: sustainable communities. This paper analyzed the impact of varying provincial carbon pricing on three wood biomass DE systems across Canada. It was determined that carbon pricing policies would help make wood biomass a more competitive renewable fuel choice.

Revelstoke Biomass DE System

The first case study was in Revelstoke, British Columbia (B.C.). This small city in the interior of B.C. relies on the forestry industry and has three local sawmills. Their DE system has ten buildings connected and produces 3.5 Megawatts (MW) for domestic hot water and heating. The system contains a 1.5 MW biomass boiler with a 1.75-MW back up propane boiler. Steam is provided to Downie’s dry kilns and hot water is piped through 2.3 km of pipe. The goal for the biomass system is to use biomass for 85% of Revelstoke’s energy demands annually, while the remaining 15% of demand is met by propane, which is used for the coldest parts of the year, or during peak demand. The system uses 4 000 tonnes of wood residue from the Downie Sawmill which is provided for free for 20 years. This system helped reduce greenhouse gas (GHG) emissions in the community by 4-5% (Think Bright Climate Solutions, 2011).

The province of BC’s carbon pricing policies for large emitters, the CIIP, is for facilities that emit over 10 000 tonnes of CO2. Since the Revelstoke case emits under 1 000 tonnes of CO2 they are unable to join this program. This means that the Revelstoke wood biomass DE system would be subject to the provincial fuel charge for propane that they use. Currently, the community’s propane costs are being subsidized which has impacted the systems competitiveness. If propane remains subsidized, the base price of wood pellets at $60 per tonne will only remain competitive if there is a fuel charge. If there was no fuel charge the base price of wood pellets would not be competitive. Propane being unsubsidized offers the best economic case for a wood biomass DE system as it creates the biggest cost differential.

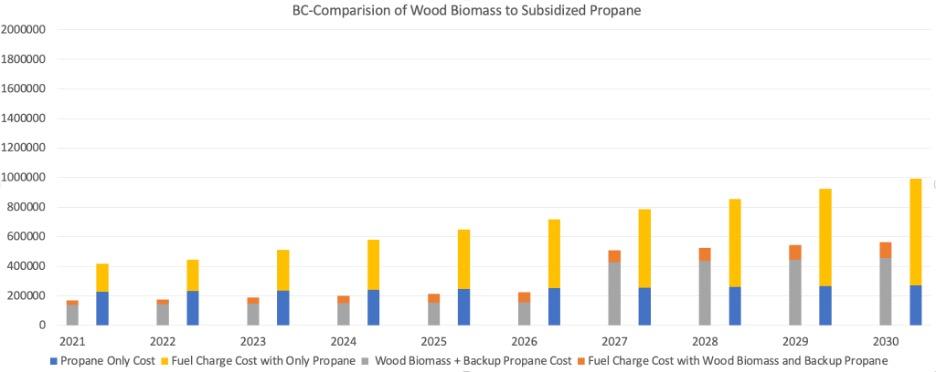

Figure 1: Revelstoke biomass DE system compared to only using subsidized propane.

This figure demonstrates the Revelstoke biomass DE system’s competitiveness against propane suppliers if the system was run completely on propane. The propane only cost demonstrates what this would cost the facility without a fuel charge. When the fuel charge for only propane is added on top, the final price is determined up to 2030.

Brehon, K. (2021)

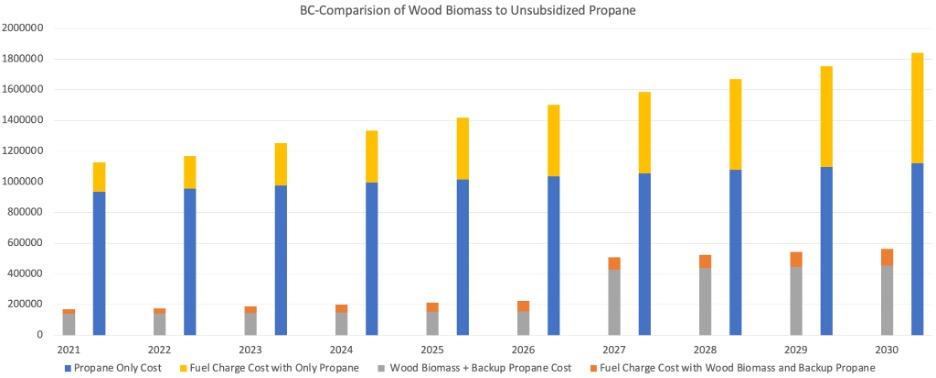

Figure 2: Revelstoke biomass DE system compared to only using unsubsidized propane

The wood biomass with propane backup is what the current system would pay without the fuel charge on the propane backup. The fuel charge price is added separately for propane the system uses.

Brehon, K. (2021)

Oujé-Bougoumou Biomass DE system

The community of Oujé-Bougoumou is a Cree Nation located in Northern Quebec’s James Bay area, 960 kilometers (km) North of Montreal. Due to the community’s remote location and the high price and volatility of oil, the community developed a wood biomass DE system which gets its saw dust from the neighbouring Barrette-Chapais Sawmill. The system connected 140 homes and 20 public buildings with 12 kilometres of pipe (Biocap Canada & EnergyNet, 2006). The heating plant was constructed with a 1-megawatt (MW) biomass boiler and an 1-MW oil boiler and in 1998 a 1.7-MW biomass boiler was added to account for the community’s growth. The system now consists of a 2.7-MW biomass boiler capacity and 2 oil boilers with a capacity of 2.5-MW. The peak winter heating capacity before the upgrade was 2.5-MW in 2000 (Biocap Canada & EnergyNet, 2006). In the winter of 2000-2001, the cost per MWh(th) to run a boiler using heating oil would have been $96 whereas using heat from biomass cost around $11 per MWh(th) (Biocap Canada & EnergyNet, 2006).

When the community was developing their DE system, costs to produce one megawatt-hour (MWh) of heat from Hydro Quebec’s electricity rates was around $72, while biomass from the local sawmill cost around $2.50. The benefit of using a biomass DE system in Quebec under the province’s cap-and-trade policy is that the system provides the community with an economically stable fuel source. Carbon pricing policies do not impact this system because it does not produce over 50 000 tonnes of CO2e. The pricing may indirectly impact the price of fossil fuels over time. Even at the base price of $60 per tonne of wood pellets, the community will pay drastically less than if they used heating oil in their DE system.

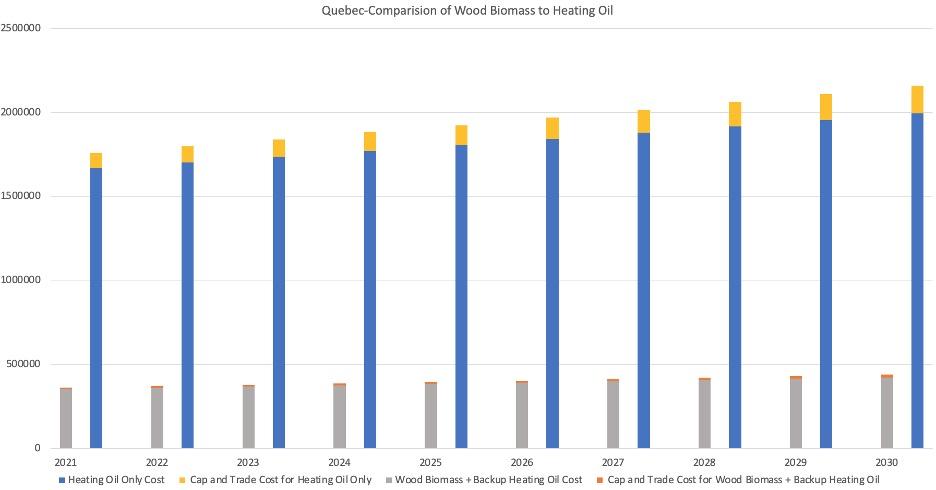

Figure 3: Quebec biomass and backup heating oil compared to heating oil only cost

The heating oil only cost demonstrates what the cost of running the DE system only on heating oil would be. The cap-and-trade cost for heating oil is added on top of the cost to demonstrate the difference. The cap-and-trade cost was determined independent of allowances for both the heating oil only example and the actual project costs. The wood biomass and backup heating oil costs are the calculated cost of the real system.

Brehon, K. (2021)

Charlottetown Biomass DE System

The community of Charlottetown, Prince Edward Island (P.E.I.) implemented a DE system utilizing biomass in 1980. It is Canada’s longest running, privately owned, biomass-fired DE system (Canadian Urban Institute, n.d). The biomass DE system in Charlottetown serves over 125 buildings which includes residential, commercial, and institutional customers (Canadian Urban Institute, n.d). The system uses wood waste and municipal solid waste (MSW) as fuel sources with oil as a backup source. The fuel ratio is 41% MSW, 42% residual sawdust and 17% oil (Natural Resources Canada, 2009). The overall system has a capacity of 72-MW and 1.2-MW for electricity (Natural Resources Canada, 2009). The system provides heating, electricity, and hot water for 4.5 million square feet of area. The DE system is connected through 17 km of thin wall steel piping (Canadian Urban Institute, n.d). By using waste and wood as biomass to replace fossil fuels, more money is retained by the community. For every dollar spent on biomass fuel, 70 cents stay within the local economy, compared to 10 cents if oil was being used (Natural Resources Canada, 2009). The system reduces CO2 emissions by 48 900 tonnes annually and sulphur dioxide emissions by 135 tonnes annually (Natural Resources Canada, 2009).

The Charlottetown case study demonstrated that larger systems could remain competitive through the use of different fuel sources. P.E.I. may end up with the full federal Output-Based Pricing System (OBPS) in the coming years. This program does not include district heating amongst the industries allowed to take part, although any facility over 10 000 tonnes of CO2e could opt-in. With P.E.I.’s current carbon pricing policies, DE systems are not as competitive as they could be. This is because the province currently does not have a fuel charge on heating oil. If this changes, alternative forms of heating and energy will be more appealing. Recognizing DE systems would encourage their implementation. The DE system remains a competitive option for heating and electricity in P.E.I. with or without a federal fuel charge.

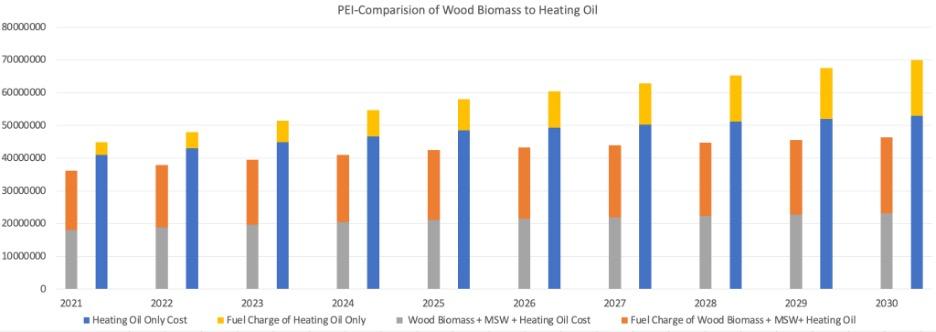

Figure 4: P.E.I. wood biomass DE system compared to heating oil only

The heating oil only bar shows the cost of only using heating oil for this system. The fuel charge for this example is added on top to demonstrate cost with a fuel charge and without one. The wood biomass, MSW and heating oil cost is the calculated price of the system. The fuel charge is calculated based on heating oil and MSW combustion to get the total cost with carbon pricing.

Brehon, K. (2021)

Final Words

These case studies demonstrate that DE systems are a viable option, now more than ever. DE systems can offer impressive energy efficiencies and a reduction in CO2 emissions while biomass can offer a carbon neutral renewable source of power. Together, a biomass DE system can provide a baseload power supply for communities. Wood residue and wood pellets are an under-utilized source of power within the country and many more communities could benefit from using them. More research with new data on current biomass DE systems in Canada would be beneficial to understanding their problems and benefits.

References

Canada Energy Regulator. (2020). Canada’s adoption of Renewable Power Sources-Energy Market Analysis: Biomass. https://www.cer-rec.gc.ca/en/data-analysis/energy-commodities/electricity/report/2017-canadian-adoption-renewable-power/canadas-adoption-renewable-power-sources-energy-market-analysis-biomass.html

Canadian Urban Institute. (n.d) PEI Energy Systems: Consolidation leads to economic benefits. https://iwmc.pe.ca/wp-content/uploads/2019/12/PEI-Energy-Systems9-25-07.pdf

Biocap Canada, EnergyINet. (2006). Strategies for strengthening the bioenergy sector in Canada. Biocap Canada Foundation, EnergyINet. https://www.cesarnet.ca/biocap-archive/images/BioenergyChallengeDialogue.pdf

Natural Resources Canada. (2009). Community Energy Case Studies: PEI energy systems Charlottetown PEI. CanmetEnergy https://www.nrcan.gc.ca/sites/www.nrcan.gc.ca/files/canmetenergy/files/pubs/PEI-EnergySystems_ENG.pdf

Thinkbright Climate Solutions. (2011). City of Revelstoke community energy emissions plan. http://www.cityofrevelstoke.com/DocumentCenter/View/2625/Community-Energy-and-Emission-Plan-CEEP?bidId=