Technoeconomic Assessment of Hydrogen Production From Municipal Solid Waste Gasification in Alberta

Behnaz Afsahi LaFrenz

Imagine a future in which a major city can generate enough zero-emission transportation fuel to run its entire fleet of vehicles, by diverting waste from its landfills! A city the size of Edmonton would require about 20 tonnes of hydrogen fuel per day to run its fleet of busses. However, one of the key environmental requirements to doing so is the ability to sequester the resulting CO2. Edmonton, being located right next to the Alberta Industrial Heartland, is in an ideal location to be a front runner in validating this market opportunity. Edmonton generates over 250k tonnes of MSW on an annual basis, and already spends hundreds of millions of dollars processing it. To address its need for 20 tonnes per day of hydrogen only requires conversion of 260 tonnes per day of its MSW, less than 40% of its daily MSW.

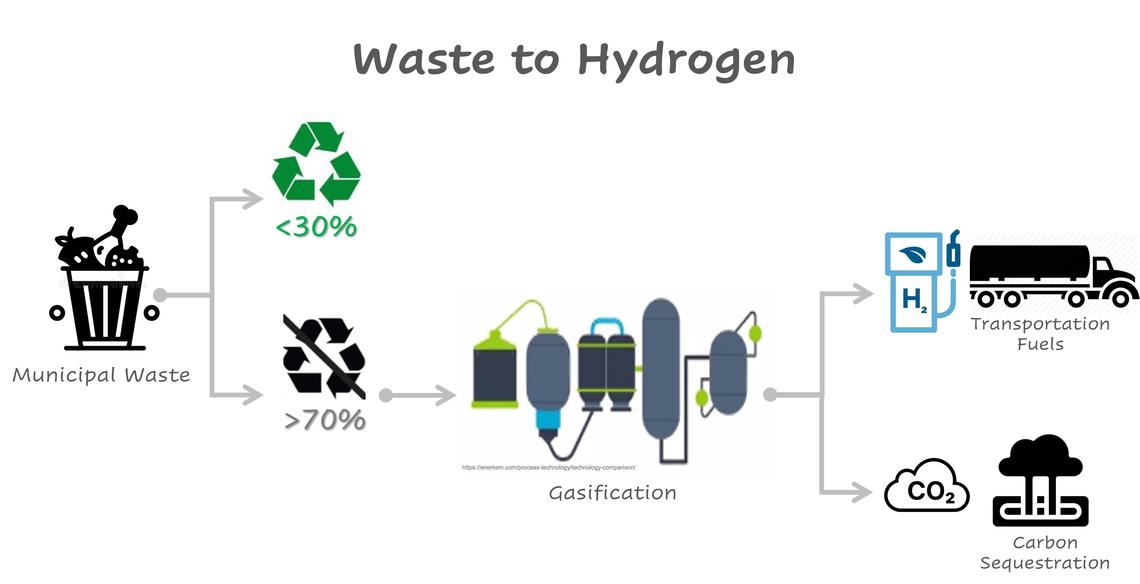

Enerkem’s biofuel facility in Edmonton are focused on producing biofuel using the same MSW gasification process due to the current high demand of biofuels. However, the new policy frameworks such as clean fuel standard may negatively impact the value of biofuels and in favor of clean hydrogen as a transportation fuel. Hydrogen can be produced through a biomass and MSW gasification process similar to Enerkem’s but with some process modifications such as addition of an amine-based system to capture the produced CO2. Air Products future connecting pipeline to the ACTL in the AIH, CAN BE UTILIZED through which carbon by-products of hydrogen production can be captured and permanently sequestered underground or used for other industrial purposes. This is a highly efficient process, as it generates much of the electricity it needs to operate through thermal recycling.

MSW gasification not only conserves landfill space (for every tonne of hydrogen produced from MSW or residual waste gasification 10k m3 of landfill space is saved per year), but it can significantly reduce GHG emissions from landfills. Canada produces more than 30 million tonnes of MSW per year out of which more than 70% is landfilled. The cumulative CO2-equivalent emission from the landfills in Canada in the past 20 years is about 650 billion cubic meters. Therefore, MSW diversion from landfills for gasification and hydrogen production can significantly reduce LFG and GHG emissions from our landfills as well as producing a negative emission clean fuel such as hydrogen.

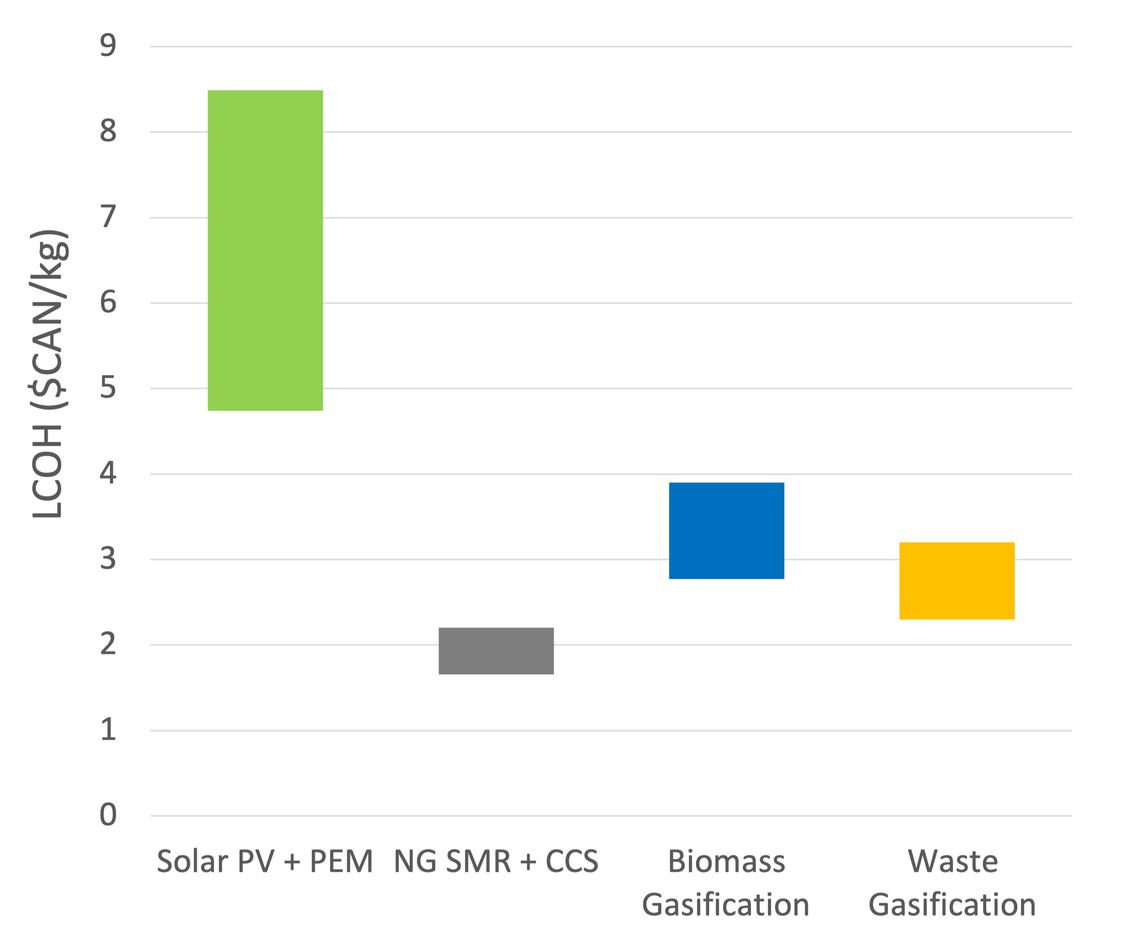

Next question is whether levelized cost of hydrogen (LCOH) from biomass and wastes is competitive compared to other hydrogen production pathways? The LOCH of biomass and MSW gasification to hydrogen is competitive compared to other green hydrogen production pathways. The LCOH from natural gas steam methane reforming (SMR) is still lower than biomass and MSW gasification. However, hydrogen production from natural gas SMR requires large scale projects and higher capital costs with much higher GHG emissions.

However, the economic feasibility of this process is heavily dependent on the current policies in place such as the federal government carbon pricing set to increase to $170/tonne of CO2 by 2030 and the current Alberta carbon price system, ‘Technology Innovation and Emission Reduction Regulation’ (TIER). Inevitably, these policies would impact the levelized cost of hydrogen compared to hydrogen production from steam methane reforming (SMR) in Alberta. With the current carbon price and credit trading system in Alberta, TIER can offset some financial costs so as to reward high performance in carbon reduction. However, modifications to TIER, such as the restructuring of the system and redesign of the benchmarks is a major uncertainty.

From a socio-economic perspective, gasification of biomass and MSW can bring significant benefits to local communities in Alberta by creating specific employment streams as well as new economic activities and networks. As a result, the early stage and growing demand for clean hydrogen, in combination with current commitments to GHG emissions reduction and waste disposal problems in most countries, creates a promising future for waste to hydrogen processes to capture a solid share of the clean hydrogen market.

To conclude, hydrogen production for transportation for a city the size of Edmonton from biomass and MSW is both technically and economically feasible. This is especially true for MSW, as there are gate fees to incentivize diversion of wastes from landfill. Biomass and MSW can also be gasified into hydrogen with negative low GHG emissions and at costs currently below that of renewables paired with electrolysis. This in turn will lead to further reductions in Canada’s GHG emissions, support the drive to carbon net zero and support the Canada wide strategy on zero plastic waste.

Figure 1. MSW Gasification Schematic and its Products

Afsahi LaFrenz, B. (2021)

(Afsahi LaFrenz, B., 2021), based on Shahabuddin et al. (2021) and Bruce et al. (2018).